2020 Guangde Dongfeng Electronics Co., Ltd. Environmental Report

2020 Guangde Dongfeng Electronics Co., Ltd. Environmental Report

Guangde Dongfeng Electronics Co., Ltd. has made great progress in 2020, through the implementation of various environmental protection work, the company's environmental protection facilities technical transformation, greatly improved the treatment effect of wastewater, to ensure up to the standard discharge, but also achieved significant economic benefits, to achieve environmental protection and economic win-win.

First, the basic information of the company

(1) The company's development history

Guangde Dongfeng Electronics Co., Ltd. (hereinafter referred to as the "Company"), the company is located in Guangde Economic Development Zone, with an annual output of 360,000 square meters of double-sided and 120,000 square meters of multi-layer printed circuit board project with a total investment of RMB 120 million, the first phase of investment annual output of 200,000 square meters of printed circuit boards, the project planning covers an area of 35 acres, a total construction area of 24,000 square meters, with a plant of 18,000 square meters. Guangde Dongfeng Electronics Co., Ltd. is a professional PCB manufacturer integrating design, production, marketing and service, the company mainly produces all kinds of high-precision double-sided circuit boards, multi-layer circuit boards and other precision PCB products; In 2019, the company won the demonstration enterprise of integration of industrialization and industrialization in Guangde City and a national high-tech enterprise, the company won the excellent growth enterprise in Guangde City for three consecutive years, and in 2020, the company created a total output value of 140 million yuan and achieved tax payment of 7.61 million yuan, and the company's production and sales reached a new level. The company constantly pursues progress and develops steadily.

(2) The industry and scale of the industry, main products and services

1. Industry: electronic components manufacturing, industry classification number is 3972 printed circuit board manufacturing

2. Scale: annual output of 360,000 square meters double-sided and 120,000 square meters of multi-layer printed circuit boards

3. Company employees: 260 people.

4. The company's main service customers include domestic enterprises.

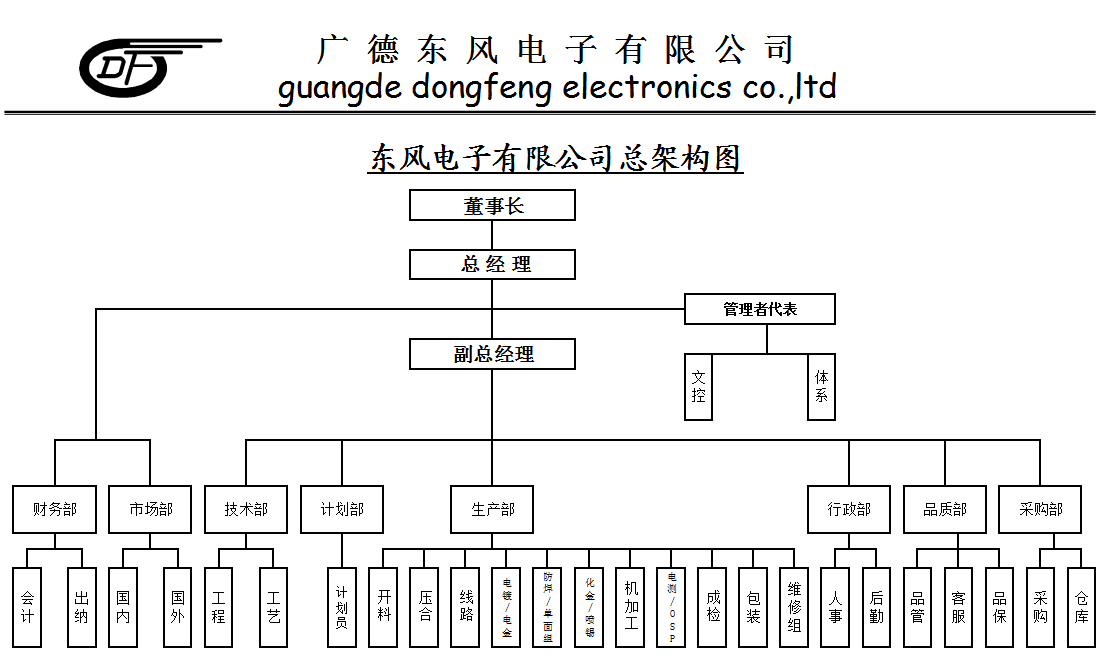

(3) Corporate structure

Second, the company's environmental management

In line with the attitude of being responsible for customers, the government and society, the company seizes the opportunity of the state to advocate the construction of a conservation-oriented society, further strengthens the operation and management of waste gas and wastewater, updates waste gas and wastewater treatment facilities and technologies in a timely manner, gives full play to the treatment capabilities and advantages of enterprises, and creates greater environmental and economic benefits!

(1) Education and training related to environmental protection

Since 2020, many training meetings related to waste gas and wastewater treatment operations held by provincial environmental protection and municipal environmental protection departments have been attended by our company to improve their professional level and grasp the latest environmental protection trends. In addition to the induction training and education of new employees, new employees also carry out environmental awareness education and related environmental protection knowledge and skills training, and can only work after passing the assessment. In 2020, the company organized four training sessions on waste gas and wastewater treatment related knowledge, with a total of more than 20 people participating. The company attaches great importance to the emergency handling ability of employees, and organizes employees to conduct emergency knowledge training every year to improve their emergency handling ability.

(2) Operation and management systems

In order to improve the quality management system of the operation division, improve the quality level of the operation project, and fully mobilize the awareness of quality responsibility and the enthusiasm of quality work of personnel at all levels of the department, a complete environmental protection management system has been formulated. In order to strengthen the effective monitoring of quality management by the operation division, and at the same time promote the quality management work of the operation division to gradually develop in the direction of rationality, science, refinement and standardization

1. Daily operation procedures

The daily operation and fault handling of the operation site are related to the safe operation of the entire on-site facilities of the operation site, and if faults are found, the faults should be eliminated in time according to the actual situation to ensure the normal operation of the operation site.

2. Operation site safety production operation procedures

In order to ensure the safety and health of the operation management personnel in the production process, prevent the occurrence of personal and equipment accidents and occupational diseases, and ensure the production safety of the site, this operating procedure is specially formulated

3. Operate on-site equipment patrol inspection system

Equipment patrol inspection is an effective means to ensure the safe and stable operation of equipment and qualified process indicators

4. Daily laboratory operation procedures at the operation site

The advantages and disadvantages of waste gas and wastewater treatment effects must rely on a variety of indicators to complete, on-site operation (need to judge the operation effect and status of the overall treatment system according to the daily test results, and use this as the basis for the treatment system to regulate and ensure the good operation of the operation site

5. Employee performance appraisal management system

Through the overall performance management, you can find the operation status of the operation department, timely understand the problems in the implementation of the development strategy, and track the action plan and performance results by correcting the strategy, so as to ensure that the realization of the development strategy can be used as the basis for employee training and development and career planning for individuals. The continuous establishment of performance files can understand the long-term performance of employees, so that training plans can be developed to improve employees' performance capabilities. And as a reference basis for employee career development process selection, job rotation, promotion, salary increase.

3. The occurrence of major environmental problems in the company

Since its establishment, the company has attached great importance to environmental protection, conscientiously implemented relevant environmental protection laws and regulations, formulated a complete environmental protection management system and standardized operation, strengthened the inspection and maintenance of gas and wastewater treatment equipment and facilities, implemented environmental protection responsibilities to people, strengthened employees' awareness of environmental protection, and so far there have been no major pollution accidents and no environmental disputes.

4. The company's environmental protection and compliance with the law

(1) The discharge of pollutants up to standards

1. Wastewater

The domestic sewage in the plant is treated by the septic tank to the third-level standard of GB8978-1996 "Comprehensive Sewage Discharge Standard", and then enters the urban domestic sewage treatment plant through the sewage pipe network for treatment.

This project sets up wastewater collection tanks, collects different types of process wastewater respectively, and transports it to the corresponding collection pool of the PCB Industrial Park sewage treatment plant through the corresponding sewage pipeline, and the sewage meets the water pollution discharge limit of newly established enterprises in GB21900-2008 "Electroplating Pollutant Discharge Standard" and the takeover standard requirements of Guangde County Sewage Treatment Plant after being classified and treated.

2. Exhaust gas

After the acid waste gas generated by the project is collected, it is sprayed and absorbed by the acid waste gas scrubber and dilute alkali, and the purified waste gas is directly discharged into the atmosphere through the 18m high exhaust cylinder, and the removal efficiency is ≥ 90%, after treatment, hydrogen chloride, sulfuric acid mist, nitrogen dioxide are discharged through the 18m high exhaust cylinder, and the emission concentration can meet the emission limit requirements of new enterprises in Table 5 of the "Electroplating Pollutant Emission Standard" (GB21900-2008).

The dusty waste gas generated by the cutting plate, edging and drilling process of the project is discharged after being treated by the pulse bag filter.

The tin-containing waste gas is discharged by an 18m high exhaust cylinder after being treated by the tin-containing waste gas spray tower, and the treatment efficiency is greater than 95%, and the emission concentration and emission rate of the exhaust gas containing tin and its compounds after treatment meet the secondary standard of GB16297-1996 "Comprehensive Emission Standard for Air Pollutants".

The organic waste gas is collected by the trough side exhaust system, and after the activated carbon adsorption treatment, it is discharged by the 18m high exhaust cylinder, and the efficiency of activated carbon adsorption treatment of organic volatile gas is 90%, and the VOCs emission concentration of volatile organic waste gas after treatment can meet the standard limit of the reference standard "Synthetic Leather and Artificial Leather Industrial Pollutant Emission Standard" (GB 21902-2008).

The alkaline gas is introduced into the scrubber by the induced draft fan, and after being absorbed and treated with water spray, it is discharged by the 18m high exhaust cylinder to meet GB14554-93 "Odorous Pollutant Emission Standard".

3. Noise

The project selects low-noise environmental protection equipment, the fan is equipped with a sound insulation cover, and the muffler is installed at the entrance and exit; The base of the pump is equipped with a vibration damping pad, leaving a vibration damping groove, flexible connection at the interface, a local sound insulation cover, and strengthening greening inside and outside the factory area, after the comprehensive adoption of the above noise control measures, the noise of the factory boundary is lower than the emission limit of the 3 types of areas specified in the "Industrial Enterprise Boundary Environmental Noise Emission Standard" (GB12348-2008), and the impact on the regional sound environment quality is small.

4. Solid waste

All kinds of acid and alkali waste liquid, waste residue, waste development waste liquid, etc. generated by the project are hazardous waste, which are safely disposed of by units with hazardous waste treatment qualifications or recycled by professional companies, and are not discharged; The scrap of the copper clad laminate generated in the cutting, edging and drilling process is purchased by the corresponding waste recycling department; Employees' household garbage is sent to a place designated by the local sanitation department for storage.

(2) Implementation of emergency response plans for environmental emergencies

In order to prevent the expansion of various types of casualty accidents and incidents, we strive to reduce the losses of casualty accidents and eliminate the seedlings of accidents in the bud. In order to promote safe production, ensure the safety and health of employees, ensure the safe and stable operation of the factory, and constantly improve the emergency management system to ensure the efficient and orderly operation of safe production and rescue work. To this end, the company has formulated the "Safety Production Emergency Plan", set up an emergency leadership group, and prepared emergency handling procedures and measures for various sudden environmental accidents to prevent them before they occur. In order to improve the skills of preventing and dealing with sudden leakage accidents and enhance practical capabilities, the company holds an "emergency rescue drill for hazardous chemical safety accidents" every year. Through drills, the company's ability to prevent and deal with sudden leakage accidents is continuously improved, and the operability and effectiveness of the company's emergency plan and implementation are tested and continuously improved.

V. Summary of the report

Guangde Dongfeng Electronics Co., Ltd. will continue to thoroughly implement the "Environmental Protection Law of the People's Republic of China" and other laws and regulations, effectively strengthen environmental protection, improve resource utilization efficiency, reduce and avoid the generation of pollutants, protect the physical and mental health of employees, and promote sustainable economic and social development; Increase investment in environmental protection funds, accelerate product technology development and research, further reduce product energy consumption, continue to make efforts for energy conservation and emission reduction, and make due contributions to the prosperity and development of the local economy and society, happiness and harmony. It is hoped that this report will strengthen the awareness of the company from all walks of life, and also hope to accept the supervision of the society to promote the company's environmental protection work better.